What is the Taguchi Quality Control Method?

The Taguchi quality control technique is an engineering methodology that emphasizes the contributions that research and development (R&D) and product design and development may make to lowering the rate at which produced items break down or malfunction.

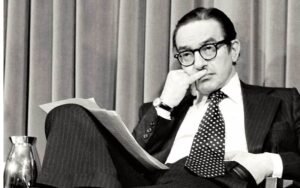

Genichi Taguchi, a Japanese statistician and engineer, developed this strategy to prevent production deviations by placing design above manufacturing procedures in quality control.

Comprehending the Taguchi Quality Control Method

The Taguchi approach calculates a product’s quality based on its social cost to society. Specifically, changes and divergences in a product’s functionality and harmful side effects constitute a loss in the product.

The comparison of the differences in operation between each unit of the product is called loss from variation in function. The more serious the loss of function and quality, the more significant the variation. This might be expressed as a monetary amount that shows how the product’s flaws have affected its use.

An illustration of the Taguchi Quality Control Method

If the product is a precision drill that has to drill holes in every material it is used on regularly, then how much the product’s units deviate from those requirements determines part of its quality. The Taguchi quality control technique aims to guarantee that every product unit will closely adhere to those design parameters and function precisely as intended via study and design.

The loss resulting from adverse side effects on society indicates whether or not a product’s design has the potential to have a negative effect. For instance, product quality would be lost if using the precision drill could injure the user due to its design. According to the Taguchi technique, efforts made during the production design phase would try to reduce the likelihood that the drill would be made in a manner that might injure the user.

From a higher vantage point, the Taguchi technique also aims to lower the cost of the product to society, for example, by developing products to operate more efficiently rather than produce waste. For example, the drill might be made with minimal maintenance requirements.

The Taguchi Method of Quality Control’s Past

In the 1950s, Japanese statistician and engineer Genichi Taguchi started developing the Taguchi technique while working on a telephone switching system for his business, Electrical Communication Laboratory. His goal was to raise the standard of items produced via statistics.

After seeing success in his home Japan, Taguchi’s ideas gained traction in the West in the 1980s and became well-known in the US. Prominent multinational corporations, including Xerox Holdings Corp., Boeing Co., Ford Motor Co., and Toyota Motor Corp., have used his techniques.

The Taguchi method of quality control is criticized.

Western statisticians have only sometimes been fond of Taguchi’s approaches. The main criticism leveled against his quality control approach is its needless complexity. Some detractors go so far as to say that comprehending it requires a degree in mathematics.

Conclusion

- The Taguchi engineering quality control technique focuses on design and development to produce dependable, effective products.

- Genichi Taguchi’s creator aims to prevent production deviations and believes that design significantly influences quality control more than the manufacturing process.

- This approach has been used by businesses including Xerox, Ford, Toyota, and Boeing.